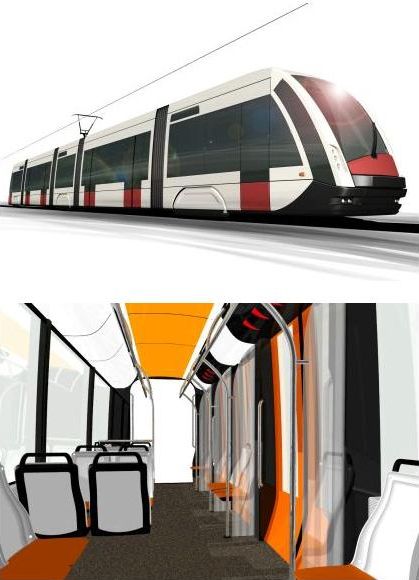

(CZ + EN) a hybridní autobus. Grafická studie tramvaje Solaris Tramino. (Solaris presents low-floor tram and hybrid bus at InnoTrans 2008)

(CZ + EN) a hybridní autobus. Grafická studie tramvaje Solaris Tramino. (Solaris presents low-floor tram and hybrid bus at InnoTrans 2008)

Berlin/Bolechowo, 19.9.2008 - První nízkopodlažní tramvaj Solaris Tramino postavená společností Solaris se rozjede na evropských kolejích v létě 2009. Projektový tým má dlouhodobé zkušenosti ve vývoji a výrobě tramvají. 100 % nízkopodlažní tramvaj je specifikována pro polský trh. Je koncipována modulárně a vyhovuje polským předpisům. V budoucnu bude rozšířeno směřování o předpisy German BOStrab. Prototyp bude článkový s pěti sekcemi. Modulární konstrukce zahrnuje od tříčlánkové 18.8 m až po pětičlánkovou 31.7 m. Sedmičlánková verze v budoucnu by byla nízkopodlažní ze 70%.

Kompletní tisková zpráva v angličtině.

Solaris presents low-floor tram and hybrid bus at InnoTrans 2008

Berlin/Bolechowo, 19 September 2008 - The increasing need for mobility requires thoughtful commitment to high-quality, high-capacity public transport for the future. At InnoTrans 2008, Solaris presents a state-of-the-art low-floor tram and an environmentally-friendly hybrid bus in hall 2.1, stand 226. The hybrid bus has been Europe’s first bus using volume-production hybrid technology since it was unveiled two years ago, while the first Solaris tram will be completed in 2009.Solaris Tramino low-floor tram

Solaris, already well versed in the challenges of urban mobility thanks to its position as one of Europe’s leading bus manufacturers, will apply the winning formula of the Urbino family of low floor city buses – reliable quality, sophisticated design and excellent comfort – to rail- based transport. The first Solaris-built tram will take to the rails of European cities in summer 2009.The project team has long-standing experience in the development and production of trams. Based on an analysis of current products in the tram industry, a modular range of tram vehicles was developed. Following consultation with Polish customers, it was decided to first build a modern low floor tram matching specifications of the Polish market. Thanks to 100% low floor construction there will be no steps either at the entrances or within the vehicle. Solaris trams will therefore offer easy access not just to mobility-impaired passengers.

The Solaris tram is based on a modular concept, initially comprising two three-section and two five- section vehicles. All current Polish regulations and specifications are met. In future, the vehicle range will be extended with versions tailored to German BOStrab regulations.

The pre-production vehicle will be a five-section articulated version. Two “sedans” will be suspended between three modules with running gear. The Solaris tram will use conventional wheel-set bogies for smooth running and highest ride quality for passengers.

The 100 % low floor tram is a modular construction allowing lengths between 18.8 m (three sections) and 31.7 m (five sections). Seven-section vehicles may be produced at a later date along with a 70 % low floor variant. The technical construction focuses on high availability and a maximum degree of reliability. Throughout, tried and tested components of experienced suppliers will be used. The construction of the body frames also meets highest expectations: as on Solaris buses, widely applied stainless steel will provide excellent resistance to corrosion. Areas subject to high stress will use carbon steel. Passenger comfort is the key focus of the interior. An integral design with a clear and recognisable theme in both interior and exterior styling makes the Solaris tram a highlight of any city.

Solaris Urbino 18 Hybrid low-floor hybrid city bus

Two years ago, Solaris Bus & Coach presented the Solaris Urbino 18 Hybrid, Europe’s first hybrid bus using volume-production technology. Based on experience gained in everyday operation, Solaris has advanced the vehicle design and this year presents the second generation of the Urbino 18 Hybrid. The state-of-the-art hybrid bus saves between 22 and 24 % of fuel and reduces exhaust emissions by up to 78 %.The Solaris Urbino 18 Hybrid uses the EP50 hybrid system developed by North American transmission experts Allison Transmission. The system is similar to a parallel hybrid system and offers great flexibility in the adjustment to customer-specific operating parameters.

As the 8.9 l, 243 kW (330 PS) Cummins engine used in the first generation of the Solaris Urbino 18 Hybrid proved on occasion to be too generous in power, the second generation utilises the Cummins ISBe5 250B engine. At 6.7 l capacity, the engine is rated at 178 kW (242 PS) and has a maximum torque of 1,005 Nm at 1,500 rpm. The engine has been adapted for the use in hybrid systems and meets the demanding Euro 5 exhaust emissions standard. Certification to EEV levels will follow soon. Thanks to the aid of the hybrid system, the diesel engine is kept running at optimum speed for maximum fuel efficiency.

The central component of the hybrid system, the EV50 unit, is mounted in place of a conventional automatic gearbox. The unit, which is comparable to an automatic gearbox in terms of size, combines two 75 kW electric engines with three planetary gearings and two synchronous clutches. The electric engines work as generators during braking and feed recuperated energy into roof- mounted nickel-metal hydride batteries with a life cycle of 6 years. The energy is then available for subsequent acceleration processes. Additionally, energy not directly needed for propulsion during normal driving is also used to charge the batteries.

While the drive train of the first generation of the Solaris Urbino 18 Hybrid was placed in the front section of the vehicle, where it powered the second axle, it is at the rear of the second-generation Urbino 18 Hybrid in the place used for conventional diesel engines. The hybrid bus is designed as a pusher articulated bus with a powered third axle. The saloon layout is the same as on conventional diesel buses, giving operators maximum flexibility in seat arrangement. Additional components of the hybrid system are mounted on the roof. The nickel-metal hydride batteries are located just ahead of the articulation, above the second axle, while the Dual Power Inverter Module and a powerful cooling unit are mounted at the rear of the bus.

Thanks to its innovative hybrid technology, the Solaris Urbino 18 Hybrid uses significantly less fuel than comparable conventional diesel buses. Comparative tests conducted by the TÜV SÜD group and Fraunhofer Institute Dresden according to the SORT cycles defined by the UITP showed fuel consumption to be 23.7 % lower in the SORT1 cycle, 23.4 % lower in the SORT2 cycle and 22.9 % lower in the SORT3 cycle.

Of particular significance for the environment and for fighting climate change is the reduction in exhaust emissions when compared to conventional diesel buses. Comparative tests with a diesel- powered Solaris Urbino 18 under road test conditions showed emissions of nitrogen oxides (NOX) to be lower by 13.3 %, emissions of carbon dioxide (CO2) to be lower by 25.3 % and emissions of carbon monoxide (CO) to be lower by 56.4 %. Emissions of carcinogenic particulate matter (PM) even are as much as 78.1 % lower than on the diesel version. The Solaris Urbino 18 Hybrid thus has excellent credentials for the provision of sustainable mobility for the future.

PR Solaris Bus & Coach

(002).jpg)

Podívejte se s námi na veletrh TRUCK & CARGO EXPO

Podívejte se s námi na veletrh TRUCK & CARGO EXPO

Busworld Europe 2025 byl rekordní

Busworld Europe 2025 byl rekordní

Reportáž z veletrhu Truck&Cargo Expo

Reportáž z veletrhu Truck&Cargo Expo